aNERDspective 23 – Adinindyah (LAWE)

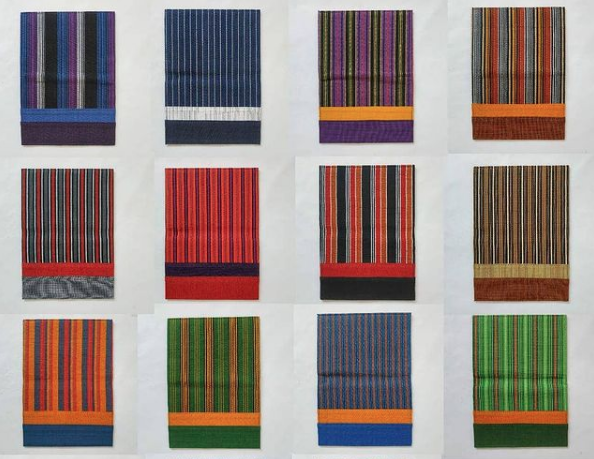

The myriad of Lawe contemporary colour palettes (Image source: Lawe Indonesia)

Adinindyah, or commonly known as Nin, is the chairperson and co-founder of Lawe, a social enterprise whose mission is to empower women through the conservation of local traditions. Since graduated with an Architecture degree from Gajah Mada University, Nin worked as a design consultant before embarking her Lawe journey in developing product, people and programs through weaving.

In this episode of aNERDspective (our NERD talk show where we converse with amazing friends about their textile adventure and perspectives), we talked to Nin about the culture behind lurik, a humble woven cloth from Yogyakarta, and her aspiration in building a Centre of Weaving Education and empowering communities across Indonesia.

Note: Full video is available on IG TV and this transcript has been edited for reading format.

Tony Sugiarta (TS): Welcome Mbak Nin to another episode of aNERDspective. It will be a casual conversation and probably we will start with a little introduction about yourself and your journey in starting Lawe.

Adinindyah (A): My name is Nindyah, I am one of Lawe’s co-founder. Lawe was founded by 5 women and I am one who is still involved in daily (operations) until today. We started Lawe in 2004. It started when me and Mbak Ifa (another co-founder) went to East Sumba. We have a natural dyes workshop and, at that time, we were amazed by the beauty of Indonesian traditional hand-woven. We saw that a lot of them do not have enough knowledge about and access to the modern market and product development, so we think maybe that’s something that we can at least give or do something about that.

So, that was in 2004, about 16 years? That is a very long time. How do you first get started with dyeing or weaving? Do you have any background in dyeing or weaving?

No, I graduated from the architecture faculty from Gadjah Mada University. All 5 founders do not have any background in business, textile, or handicraft. We are just people who take part in social activity, part of NGOs in Indonesia that work with the grassroots to develop people, especially women development. That is how we get together and think about Lawe. For myself, after I graduated, I worked as a design consultant, so I work on interior design, architecture, landscape, artwork. At that time, I learned and fell in love in Indonesian heritage, including traditional hand-woven textiles and carvings, etc.

You went to Sumba to teach the women under a program while working in the NGOs?

Yes. So, we went there under NTFP’s program, it is a Non-Timber Forest Products – Exchange Program. We work on a barrier or a greenbelt of a forest. At that time, we did not have any idea about traditional dyeing and weaving. So, we just want to share knowledge that we found. We have a good trainer from Yogyakarta who teaches about natural dyes and asked him to share the knowledge in Sumba and we learned a lot from people in the village because they are smarter than the trainer.

We had two groups at that time. The first group still started with the basics from weaving and we shared to the weaver how to dye using natural dye. However, not in a traditional way, we introduce a faster way to use natural dyes. We also have an opportunity to visit another group which is more senior and is already advanced in natural dyes. Actually, they can learn from each other, but sometimes they do not see around themselves. They just stay in the village and ask (for instructor) from far away to teach about something. Actually, the knowledge is around them.

You mentioned that they are even smarter than the teacher. They have incredible knowledge that has been passed down since a very long time.

Right.

Definitely it has been an eye opening and it is very surprising that you started with Sumba, now that Lawe has a lot of lurik. How is the transition picking up Lurik vs East Sumba’s textiles?

Lawe does not specialise in Lurik actually. We want to work on all Indonesian traditional hand-woven cloths. But, in the NTFP, we were based in Bogor and our work area is around Indonesia, like Lampung, Kalimantan, Sumba, and so on. After I got married, I moved back to Yogyakarta because I am from there. That was also the first time I understand that Yogyakarta has a traditional hand-woven called lurik. You know that everybody in Yogyakarta and Solo only know about batik, including me. At the end of 2004, I moved to Yogyakarta and I thought, if we are based in Yogyakarta, what kind of traditional hand-woven we can start with? So, we work with lurik.

Are all the 5 co-founders from Yogyakarta?

Two of us originated from Yogyakarta and the other three are from Kalimantan, Lampung, and Jakarta.

Well, each area has their own textiles that can be explored, definitely. Back to lurik, so you started Lawe when you were in Sumba or when you moved back and started working with lurik?

When I moved back to Yogyakarta and we started to develop the product.

Probably we can start a little bit about lurik itself. Perhaps, you can share a little bit about it: what is lurik and the history about lurik?

Lurik is the simplest technique of weaving and it already started in the 9th century. You can see the proof in museums located in Surabaya and you can see a lot of artefacts that prove that lurik has already started long ago. Lurik itself is started from the people, not like batik that started from the palace, so it is like the people’s cloth. The interesting thing about lurik is that they have a humble philosophy. Lurik means line, and also means the protector of a castle. People believe that if you use lurik, it will protect you.

Interesting. So, it is the people’s cloth that was picked (for use) by the royals later on?

The royals, like the king, only use lurik when it comes to drought season. There is a special motif called Udan Liris or drizzle. The king will use this motif to ask for rain. Other than the king, lurik is only used by palace’s servants or armies. Actually, it is not for the people with the high position.

I see. Is there a name for motif (behind you)?

It is called lurik ketanggung. Sometimes people choose names like drizzle, spinach flower (kembang bayam), etc. It is kind of everyday’s life.

I found it very fun that one of the patterns is called gerimis, which means drizzle?

Yeah, that is Udan Liris. And the special one that is used by the royal servant’s uniform, it is called telupat. It means three and four. It is actually to show the connection between the king and the people is very close like number three and four.

What are the three and the four referring to? Is it the number of yarns?

On the motif, there are three stripes and four stripes and they are together. People is four in Javanese language, called pitu. From pitu, we said pitulungan or help from God. There are a lot of prayer on that cloth.

Lurik Telupat, symbolises the close relationship of the king and his men. (Photo source: astinsoekanto.com/)

As you said, the name lurik means vertical lines?

Yes, lines. There are three kinds of lurik. First is line, second is a checkered, third is the plain one. Like the blouse I use, this is the plain one.

I would like to talk more about transforming the traditional cloth into lifestyle products. If you can share the creative process behind it, how do you choose a product or how do you make it into something more modern?

We do not have any background in business or in product development, so what we did was trial and error. We tried to develop products based on our perspective and our reference. Me and another co-founder, Ani, were very attracted to stationery. At the beginning, we developed stationery, such as book covers or pencils. It started from love and the fun of doing that. After we had a lot of product samples, we asked our friends, is it good? Does it have potential in the market? Do they want to buy this kind of product? But when we talk about the price, they usually do not like the price, because it will be quite pricey if you compare with stationery produced by the factory. We started to talk to our expatriate friends. They are more attracted to hand-woven and hand-crafted products. So, they started to buy the products for their Christmas gifts, souvenirs for the event and that is how we started.

They are all definitely very practical and it is very attractive. I like the colours that you guys offer because they are bright. How do you do that colour combination?

We have a principle that everybody who buys or uses our product, they will feel the happiness, the aura that we want to share with the customers. Actually, we never have a monotonous colour combination, so sometimes people say that our colours are really contrasting. We refer that from nature, like our bird series. We produce lurik with colours of the birds from Indonesia, they have contrasting colours but it can blend well, so we learn a lot from nature.

Really nice. So, I guess mostly (will be playing with) different colour combinations. It is hard for me to imagine, especially since lurik is vertical and it is limited in that sense in terms of motif so you have to play with colours.

Right. It is quite hard to work with the weaver’s group for the first time because they are used to produce weavers that are of gloomy colours or dark colours – colours used by the palace armies, or black. We found that our customers want more attractive colours, but when we asked them to develop new colours, they do not believe that. We tried to give them samples from outside Indonesia that we brought from Philippines and we showed them how beautiful it is.

At first, they said that they are not sure about the market and they asked Lawe to buy everything if we asked them to produce the contemporary motif / colours. We started with a very small amount of money and we tried to borrow money from everywhere, so we agreed that we would buy the whole woven and they said okay. Then they started to develop the new colours. In the middle of the process, another guest comes to their workshop and they love the colours, then the weavers (started to) believe us. After that, they can produce other combination of contrasting modern colours, like what we see right now.

What are the traditional colours other than black?

I have these traditional colours that they use dark brown, black, and dark blue.

Similar to the batik colours.

Yeah, like sogan.

Are the yarns individually dyed by the artisans?

Yes.

And do you actually supply them with the dyes for Lawe’s projects?

We asked them to provide us with samples of another colours other than traditional colours. They provide the dyes themselves.

So you guys develop the products and the yarns for your products?

Yes, we design the stripes and the motifs. We design the products after they weave the cloth.

When you started, how did you get the weavers, personal contacts or (is there a) weavers’ village in Yogyakarta?

We started to contact weavers from recommendation, from my mother-in-law actually, then we visited them. Actually, my husband’s family has a hand-weaving textile business. So, before I got married, in his house, there were still weavers doing napkins weaving. After his grandfather passed away, the business dropped. We still have the loom in our house and it is still sitting there until today. The group of weavers in Yogyakarta is actually the colleague of his grandfather. So, we visited this group and we started to develop the pattern together.

Do you weave yourself?

Oh, it will be disaster *laughter*.

No, I can not weave. I tried, but there is not enough patience.

People always say, when I retired.

Really? *laughter*

How do the weavers work with you? Are they employed by Lawe or are they independent weavers but they sell the cloth to Lawe?

They are independent. So, we work based on projects. In Yogyakarta, we are not only working with 1 weaver. Today we work with 2 groups of weavers in Yogyakarta, one group in Bali and North Lombok, and another group in Central Java. They are the main suppliers.

How many weavers in total have you engaged?

We work in groups, sometimes one group consists of 20-30 weavers. Now we work with 4 groups of weavers. So, you can say about more than 50 weavers.

What is the age range of the weavers?

You can say, from 40-70 years old.

I am very curious if there are younger weavers to pick up the skills. I think it is, not a problem, but an observation across different artisan communities of weavers or batik makers. They have a struggle in regeneration that the young ones do not want to pick up the skills. How is your experience when working with these communities?

I can share with you. We have a program called Weaving for Life, a project under Teras Mitra Organisation. We work together with some groups of artisans to start the regeneration process in their groups. We started from North Central Timor and Bayan Village in North Lombok. They already have a group of children who want to learn how to be weavers. They started from 6 years old and they can already produce a shawl. We need to introduce to children at that age the beauty of their heritage and the fun of weaving. In Bayan, the group of children are not only coming into the workshop to weave, they learn everything including how to draw, to cook together, to play, and in the middle of their play(time), they learn how to weave. We do not want to engage in child labour in this organisation.

We want them to embrace themselves that they are the designers of these woven (cloths), so they can create a new pattern themselves.

Interesting. I want to talk more about what are the programs that you have when working with these different communities? I believe you have some kind of training or welfare programs that you might be able to share?

Actually, Lawe is the centre of education for weavers, handcrafters, and artisans. Starting from 2006, after the Yogyakarta’s earthquake, we already started our first training of product development. We have some trainers, from North Sumatra until East of Timor Island and we conducted a lot of technical training.

Together with the weavers, we look back to their roots, to see the philosophy of their cloth and their hand-woven textiles, and then we bring them back to become designers themselves. Usually they only do what their mom or their grandmother do. Like the pattern, they usually make an ancient pattern or traditional pattern. We want them to embrace themselves that they are the designers of these woven (cloths), so they can create a new pattern themselves.

We also share how they can identify the good quality products. For example, when we visit Timor Island usually chew sirih pinang (betel nut) when they weave and sometimes that make a red dot on the woven cloth. They do not even realise that it lowers the quality of the weave if they chew betel nut while weaving. We like to introduce what the market wants and the need for a quality standard. It is not easy to do because it is connected to people’s habit. The weavers said that they have already woven that way but they need to be more disciplined.

It is about changing mindset, I guess.

Yeah, so that is why we have a lot of hope working with this young weavers with regards to the quality and (designing) modern patterns. We can then develop the products from those patterns. It will be very interesting.

Do you have any criteria of which community you work with?

The only criteria is that if the community wants to learn, we will help. That is the only criteria because even if you have a very great program and supporters, and we go to the village but everybody does not want to learn, it is nothing.

So, basically is the willingness to learn.

Other than colour and design, you also do natural dyeing as well?

We introduce the natural dyes to the weavers in Central Java and in Yogyakarta. A lot of them use synthetic dyes and we want them to learn how to produce the cloth with natural dyes. But the domestic market is not good (ed.: big) enough for natural dyes and we have difficulties on stabilising and standardising the colours. So, you need to make it as a one of a kind piece of cloth.

Do the weavers plant their own dyes or do you supply them with dye materials as well?

A: So, usually we have a separate group to do the dyeing. Sometimes the weavers group does not have enough knowledge to do the natural dyes. So we asked another group that already has an experience in natural dyes and we dyed the thread there. We then send the yarns to the weavers.

Can you tell us some of the challenges while running Lawe? Perhaps, if you have some stories that you can share?

Challenges come in different ways in every steps of our journey. Our first challenge is to sell the product. In 2004 when we started to produce a Lawe product, like I said before, a lot of expatriates in Yogyakarta became our customers, but we want to penetrate into the domestic market. There is a big handicrafts exhibition in Jakarta, a yearly exhibition called INACRAFT. That is our first year to join in INACRAFT. As the rent is very high, we just send the goods to our friend who has a booth there and they ask if they can sell our product. In 2004 we tried to sell our product in INACRAFT and the result was not very good.

Then in another year, in 2006, another friend has a booth there and they ask to borrow our product and the sales is worse than 2004. At that time, we thought that maybe we ran a wrong business.

As we want to try for the third time, in 2007, we joined INACRAFT by ourselves. We got funded by Samdhana Institute at that time. Surprisingly, it went well. A lot of goods were sold and we think that that is the power of the story behind the product because in 2004 and 2006, they only sold the goods without the staff (to explain). In 2007, we are in this booth from 10 AM to 10 PM, we were like broken tapes. When somebody asked about the weaving, we will say, “Okay, this cloth is 70 cm width and it consists of two thousand one hundred threads, we put the weave one by one. So you can imagine how the effort to produce these clothes.” So people will start to see the product and get interested in this product.

That is the power of storytelling because you are there to tell the story.

It is like pushing one button and you can hear. Different kinds of challenges are about the financial, support, production competition and quality assurance. It is always in this cycle. As we learn about Kaizen or continuous improvement, we learn every day until today.

Oh, you input Kaizen into your production as well. Very nice! You mentioned that there is a difference in terms of the products that you sell for the domestic market versus overseas market. Do you make any changes to the product design?

Not really, not drastically different, but sometimes people abroad ask for less accessories of the product. For example, at an autumn bazaar for Houston market, the buyer said, “can you remove the ribbon or can you do these colours of autumn?” Basically the product is our domestic products, but when it comes to the outside market, we try to simplify that.

Talking about challenges, how is COVID doing for Lawe?

Our products are tertiary products. As we said that Lawe sells “gifts from Indonesia”, so we depend on the tourism industry. The airport is closed, the places of interests are closed, our revenue actually dropped to 50% and then became only 30%. Now we struggle to bring it up again. But I hope it is already on the next normal, so we cannot go back on the previous condition. We need to develop (and adapt) to our new condition also.

Normally, how do you market or sell the products? Do you put it in a store or just online? How do you normally do it?

A: Our biggest revenue comes from merchandise so it is a bulk order from companies or events. Also from consignment at gift stores. We have a lot of gift stores that carry our products, especially at the airports.

But now, because it is closed, that revenue stream is closed, for now.

Yeah, so like what everybody does, we also develop masks. For this mask line, we develop another (product) group, such as mask with bandana, mask with hat or mask with the pouch. We bring more groups of products based on this issue. We also open an online market(place) because previously we are not working hard to market our product online, so we need to do it right now. Every customer is now going to the online market so we need to (adapt to) the market.

Yes. Definitely. I think first is matching stuffs, so matching mask with anything such as headbands. So anything that is on the neck and above, good for Zoom meetings.

Yes, it is hard to sell shoes or pants right now.

Exactly yes. Headbands, shawl, scarf maybe. Talking about marketing products, I am not sure if you have any insights. Some of the response that I have of using tenun, as we mentioned that it is a very ordinary stuff and you use the colours to make it more modern. Also, another feedback is that it is thick and uncomfortable to wear as an apparel? Do you have any experience in designing apparel with lurik or weave cloth?

Yes, that’s why a lot of our apparel products are outers or jackets, and so it is not that directly (in contact with) your skin. We work together with the designers and we design a lot of outers actually. And the products that Lawe scores right now are bag and bag knit to thick cloth. So, it is already matched with our knit.

I want to talk about some of the programs that I saw on your website, the first one is Lawe Love Earth. Can you tell us more about that?

When we started Lawe, five of us who are the co-founders, we are environment enthusiasts. So Ani does not want to waste any part of the woven cloths. It becomes a zero waste from the beginning. So we tried very hard to make the patterns very effective. That is why you rarely see our products with round patterns. Usually we use squares and rectangles so we can cut it effectively. That is what we start with the zero waste program. After that, if we still have the scrap, we will produce another tiny item. And then the most tiny scraps, we will use it on the scrap class with the children. They can make like collage on paper so we can introduce this hand-woven tradition in a fun way. So usually we have a session in the class. We show them a video of how the woven textile is produced and we play using the cloth with them.

So to get them interested in the weaving process, it is through fun and play.

Yeah, some kindergarten groups went to our workshop before COVID and actually we miss that event. We miss their energy.

All gathering activities have to be minimised. Definitely a struggle for everyone.

Yeah, but, we need to do what we need to do.

So you did zero-waste cutting and you use natural dyes as well as part of the green initiative by Lawe.

We also have some designs that refer to this green lifestyle such as folded shopping bags, books or block notes. That is one of our products that we want to promote now. For the folded shopping bags, we set it across the countries also. We just send it to the United States. So we hope that we can extend to this kind of market.

The other program is the Sisterhood of Lawe, would you be able to share more about that?

Our mission is to work with the whole Indonesia traditional hand-woven cloth and it is impossible for Lawe to work alone. So everywhere we go, we will motivate people to do the same thing like what Lawe does. We usually meet another women that have the same love for the hand-woven cloth like us. Sometimes, we found a friend who wanted to develop cloths from North Sumatra or Sulawesi. We already worked together with about 15 women on doing this Sisterhood of Lawe.

15 individual women or groups?

15 individuals. So basically they already have their group of weavers and then they send the cloths to Lawe. We will then discuss what kind of market segment they want to target. Then we developed the product together and the production process will be done in Lawe. We will send them the finished product, and they will market it by themselves.

I see, so you are helping them with training and the product development, but doing their own selling and marketing?

Yes so they have their own brand, but we usually ask to put the Sisterhood of Lawe tagline into their brand so we are on the same circle.

Sounds really cool. Is it open to anyone or are there some criteria?

No, just the people who love to develop products with traditional hand-woven cloth of Indonesia.

So it is opened for guys too.

Yes, we have guys at this Sisterhood.

How long is the program? How is the commitment like?

It depends on them. We do not have any specific time schedule, but usually in the product development process we need about 1 and 1.5 month to bring samples to them. After that, they can choose or match into their target products. After that, the production starts, followed by their marketing and then it’s rolling like that. Sometimes, some of them, not all of them, visit us in Yogya, visit our workshop and we will discuss on another product developments. In their own speed actually.

The only criteria is that if the community wants to learn, we will help. That is the only criteria because even if you have a very great program and supporters, and we go to the village but everybody does not want to learn, it is nothing.

What is next for Lawe, are there any upcoming projects?

We still work in this Weaving for Life project, so we want to expand the groups. Until today, we already did this project with seven groups until today. Sometimes people just call us and say “Hey can we donate some money to support your programs?” That is how we are still going until today because of supporters on our journey who want to support in any way. Sometimes there are people who want to become a volunteer and they ask when we will go to the village because they want to join. So it is a very interesting process.

Also, as we still cannot do (in-person) workshop now, we want to get millennials onboard so that they can learn about traditional hand-weaving and how they can support in their capacity, like on the education, on the campaign, on the marketing process, etc. We want to involve this youngster to promote our traditional ancient heritage.

Are you working with any organisations to do that?

Right now no specific organisation is working with us. But, for some years we got support from The GEF SGP. It is a Global Environment Facility Small Grants Programme for Indonesia. It is together with UNDP and we also work together with UNESCO so some of our training is supported by them. There is not a specific organization that we work together with. So every organization who wants to support Indonesian traditional heritage, we are open to it.

For yourself, what do you wish for Lawe? What are the action items or goals that you would like to have for Lawe, but you have not achieved it?

Our long-term goal is to become a Center of Education for weavers and artisans. It is already being done on a small scale as there are actually a lot of groups of artists, weavers or crafters, who came to Lawe and learn on a specific training of the business. Or, they do come as interns.

For example, today we have transgender women who work with us and they learn together with us. We open an inclusive education, be it opening a class for mute students or (working with) colours with mental health children. There are a lot of things that we want to do in Lawe and I hope that in the long term, there will be good impact. It is our dream. Because as the business is still small, the impact will small. Hence, we want the business to become bigger, so the impact can become bigger also.

Definitely, it will be an exciting journey to find out more about how we are growing this especially in terms of educating about traditional textile. That knowledge is lost along the way and it is very heartening to hear that you are continuing the effort to do that.

One final question before we close off the conversation today. Do you have any final words on the hopes for Lawe or Indonesian textiles in general?

In Lawe itself, we build Lawe as a place for people to learn. We are not building a business, we build people. On the weaving tradition in Indonesia, I hope that there is a regeneration that goes smoothly and (as we) go into the future, I hope that people have more appreciation towards this tradition.

Thank you so much for sharing your stories. It is fun and very inspiring.

We hope you enjoyed this episode of aNERDspective. Check out the previous episode on IGTV and our gallery and store if you would like a piece of Indonesia for your home or wardrobe. You may also check out Lawe Indonesia for their latest Lawe Indonesia’s collection.

Photo credit: Lawe Indonesia, unless stated otherwise.

CONTACT US | TERMS OF USE | PRIVACY POLICY

© 2024. NERD VENTURES. ALL RIGHTS RESERVED.

0 Comments